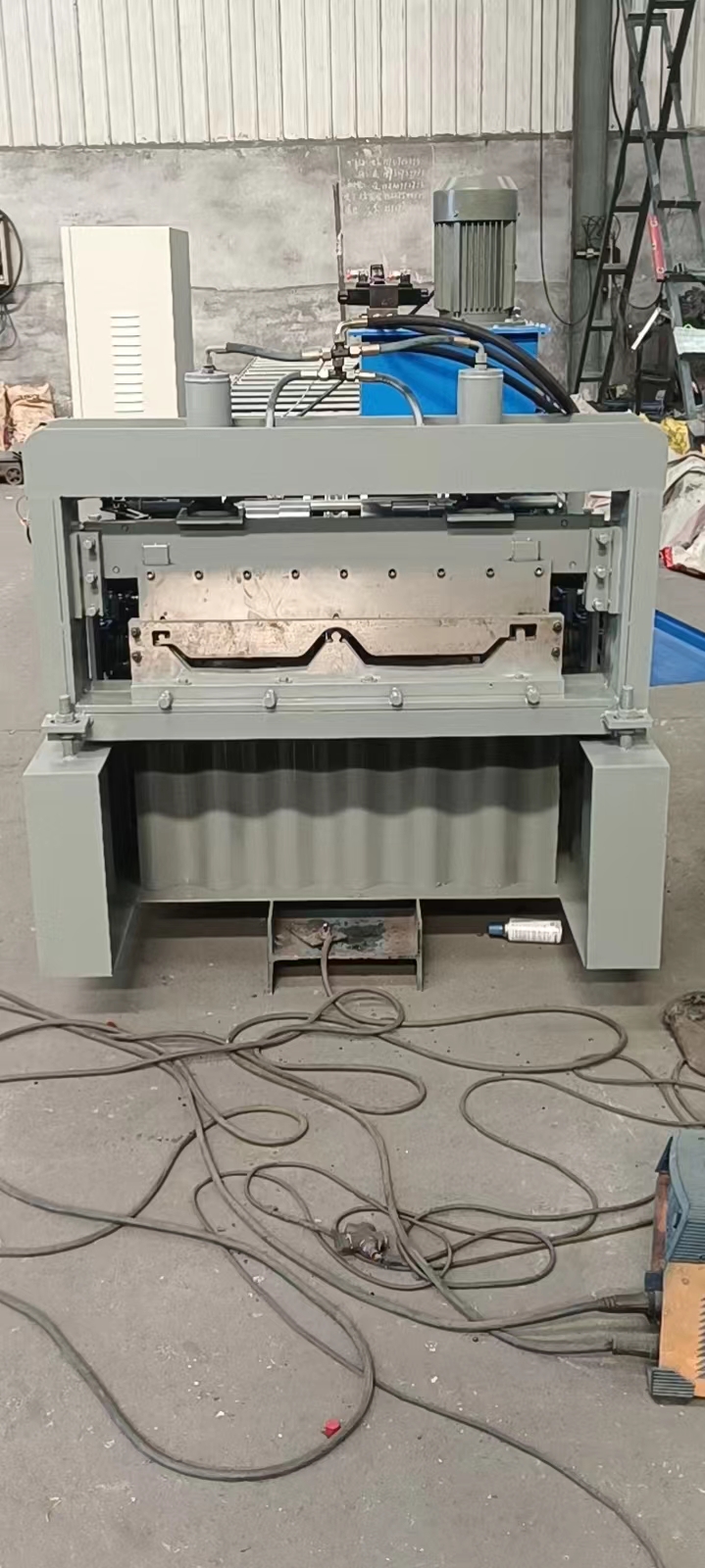

820-type corner-locked color steel tile press machine

Configuration and technical parameters of 820 corner-locked color steel tile press machine.

The configuration and technical parameters of the 820 corner-locked color steel tile press machine may vary slightly depending on the manufacturer. The following are some common configuration and technical parameter information:

-

Basic configuration:

- Machine body structure: The machine body is welded with high-quality steel. For example, some are welded with 450mm H steel to ensure overall stability and sturdiness. The middle plate part is often welded with 14mm steel plate, which can withstand greater pressure and impact.

- Forming shaft: The shaft is generally made of 45# steel and is processed to have high strength and wear resistance. The processed shaft size usually reaches a certain standard. For example, the diameter may be around 70mm.

- Forming wheel: The mold wheel is also made of 45# steel and processed, and the surface is hard chromium plated. This can improve the hardness, wear resistance and corrosion resistance of the forming wheel and prolong its service life.

- Transmission system: The transmission mode is mostly sprocket and chain transmission. The common specification of the chain is 1 inch. The transmission system design of some machines is more complex. For example, rows 1-10 are 1-inch single-row chains, and rows 10-19 are 1-inch double-row chains to ensure smooth and reliable transmission.

- Hydraulic system: The hydraulic station is an important part of the equipment and is used to provide power for operations such as shearing. The hydraulic station is usually equipped with hydraulic components such as gear pumps, and the motor power is generally about 3kw – 4kw.

- Control system: Adopting a high-intelligence industrial electronic programmer PLC frequency converter control system, the operation is simple, the accuracy is accurate, and the performance is stable. Some are also equipped with text screen display for easy operation and monitoring.

- Raw material support frame: The raw material support frame plays the role of supporting and transporting raw materials. The support frame of some machines is manually adjustable and easy to operate.

-

Technical parameters:

- Installation size: The overall dimensions of the equipment are usually large, generally within the range of length 8600mm – 10500mm, width 1300mm – 1400mm, and height 1200mm – 1400mm.

- Equipment weight: The whole machine weighs about 3600kg – 5500kg.

- Main engine power: The common main engine power is 4kw – 5.5kw, which can provide sufficient power for the operation of the equipment.

- Number of forming rows: The number of forming rows is mostly 18 or 20. The more rows, the more ideal the forming effect.

- Forming speed: The forming speed is relatively fast, generally 8-10 meters/minute, which can meet the requirements of high production efficiency.

- Thickness of rolled material: The thickness of the color steel plate that can be processed is between 0.2mm – 0.8mm, which is suitable for most production needs of color steel tiles.

- Feed width: The feed width is usually 1000mm, and the effective coverage width is 820mm, which conforms to the production specification of this model tile press.

- Length sizing accuracy: The length sizing accuracy is relatively high, generally less than 2mm, which can ensure the dimensional accuracy of the product.

- Computer control accuracy: The computer control error is relatively small, usually about ±1mm.